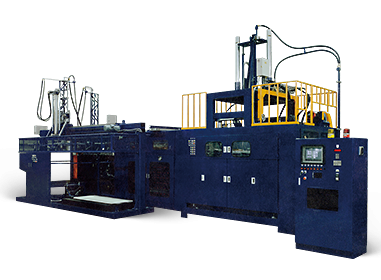

| MODEL | FLT-9602 | |||||

|---|---|---|---|---|---|---|

| Main forming products | Door liner of the refrigerator, automobile components and building material | |||||

| Materials | ABS, HIPS, etc. | |||||

| Forming Method | Vacuum forming | |||||

| Sheet feeding method | AC servo motor driven, spike chain type | |||||

| Heater | Ceramic heater | |||||

| Forming Table Driven | Air cylinder | |||||

| Max. Forming Area (W x L) |

mm | 1000 x 2000 | ||||

| Max. Forming Depth | mm | Height of formed part positive: 250 negative: 600 |

||||

| Max. Upper Mold Clamping Force | kN | 13 | ||||

| Max. Lower Mold Clamping Force | kN | 30 | ||||

- All specs and dimensions are subject to change without notice or may differ depending on export destinations and manufactured year.