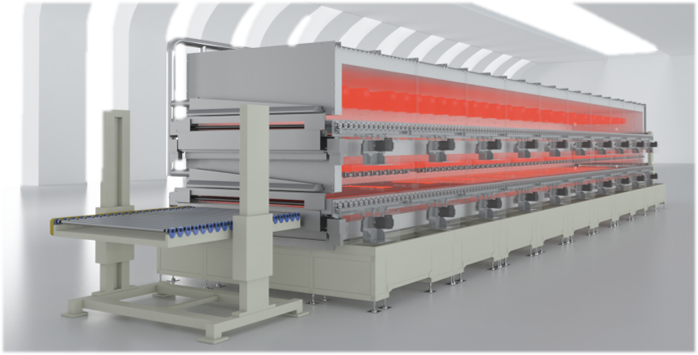

Roller Hearth Furnace for Hot Stamping

Roller Hearth Furnace for Hot Stamping

Hot stamping is a process in which sheet metals are formed and quenched at the same time creating stronger lighter parts; in turn improving vehicle safety and a reduction in fuel consumption.

- Save in running cost by up to 40%

- Energy saving by decreasing running cost by up to 15%

- Space saving by decreasing machinery footprint by up to 45%

Having the consumer in mind, we have made tremendous improvements to reduce machine downtime and consumables while increasing operation and product reliability.

Contact us for more information

- | Daiichi Jitsugyo (America), Inc.

- | 630 361 6052

- | 630 875 0422

- | Automotive Machinery Sales - APD@djausa.com

- | 939 A.E.C. Drive, Wood Dale, IL 60191