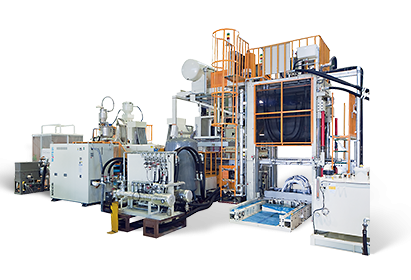

| MODEL | EFL-960-40 | |||||

|---|---|---|---|---|---|---|

| Main forming products | Mud-guard, fender liner, automobile components, etc. | |||||

| Materials | HDPE | |||||

| Forming Method | Vacuum and pressure forming | |||||

| Forming Table Driven | AC servo motor driven | |||||

| Max. Forming Area (W x L) |

mm | 1000 x 2000 | ||||

| Max. Forming Depth | mm | Height of formed part positive: 600 negative: 100 |

||||

| Max. Mold Clamping Force | kN | 400 | ||||

| Trimming Force | kN | 600 | ||||

- All specs and dimensions are subject to change without notice or may differ depending on export destinations and manufactured year.