PCB Handling Conveyors

Magazine Auto-Width Conveyor

• Adjusts the width automatically by insertion of a magazine into the conveyor by an operator.

• Adjustment range: 50 mm ~ 250 mm

Magazine & Vacuum Loader (Combination)

• Bare board and the PCB from Magazine

• Bare board loading at rear position

• Fixing with 4 Magazine fixtures

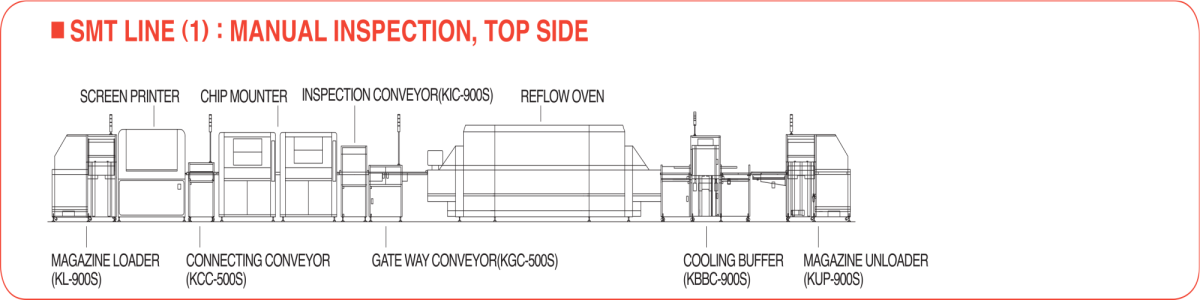

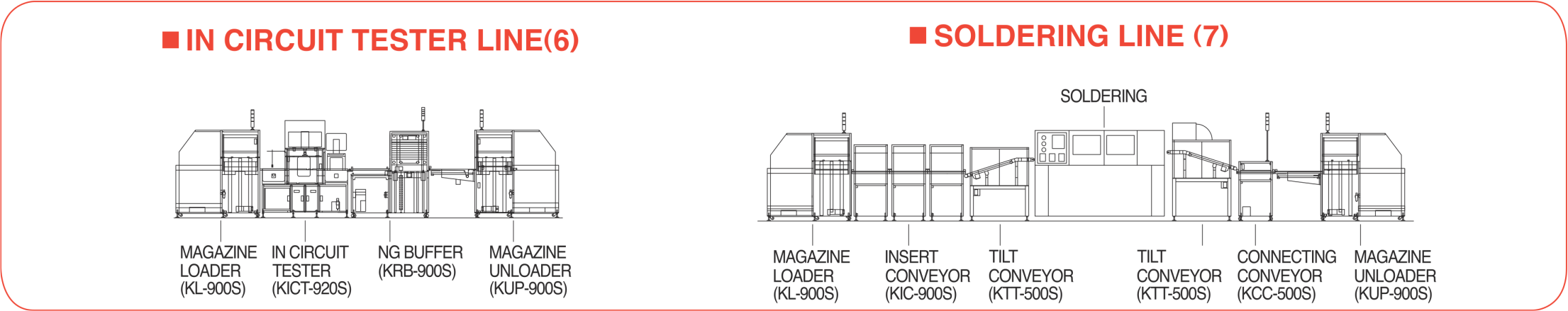

Connecting Conveyor

• Connect previous/next machine

• SMEMA Interface

• Stable design with double plate structure

• PLC control

Gateway (Telescopic) Conveyor

• Passage for operator in the production line.

• SMEMA Interface

• ESD Cover safe from dust

• Normally open type

Shuttle Conveyor

• Connect Dual with Single lane and or as a fixed rail changer.

• SMEMA Interface

• Customized rail length and sliding stroke available

• Auto/pass mode available

SPI / AOI NG Buffer

• Located after SPI/AOI process to store NG PCB in the Rack while transferring Good PCB to the next machine in FIFO or LIFO way.

• PCB Anti-touch operation – No Stress on PCB (Operated by Special Magnetic Roller)

• Output Conveyor Two-way type : upper conveyor for NG PCB

• PCB transfer in FIFO / LIFO available

Cooling Buffer

• Station to cool the PCB after Reflow Oven in FIFO way.

• SMEMA Interface

• Excellent cooling by using total 8 cooling fans

• Individual Belt running to each loading section

• PCB transfer in FIFO / LIFO available

Magazine Buffer

• Store NG PCB into the Magazine while transferring Good PCB to the next process

• Additional Function of buffer, Loader and Unloader

• SMEMA Interface

• Able to use as FIFO/LIFO NG Stacker, Loader, Unloader

Inverter (Board Flipper)

• Flip the PCB for double side assembly.

• SMEMA Interface

• Easy operation

• Reduced tact time by removing backlash process after turning.

• Buzzer, LED tower light

90° Turning Conveyor

• Turn the PCB in 90° / 270° in the production line.

• SMEMA Interface

• Easy operation

• Buzzer, LED tower light

NG Reject Conveyor

• SMEMA Interface

• Easy operation

• Buzzer, LED tower light

Manual Insertion Conveyor

• Connect previous/next machine

• Set up multiple stations as per assembly process

• Ergonomic design

Contact us for more information

- | Daiichi Jitsugyo (America), Inc.

- | 630 361 6052

- | 630 875 0422

- | Automotive Machinery Sales - APD@djausa.com

- | 939 A.E.C. Drive, Wood Dale, IL 60191