Our extensive experience and achievements in the Electronic industry demonstrate that we understand and meet our customer needs. We have all the know-how to design and manufacture machinery with the best cleaning technology and most suitable solution for various cleaning processes.

Vacuum Bake Cleaner

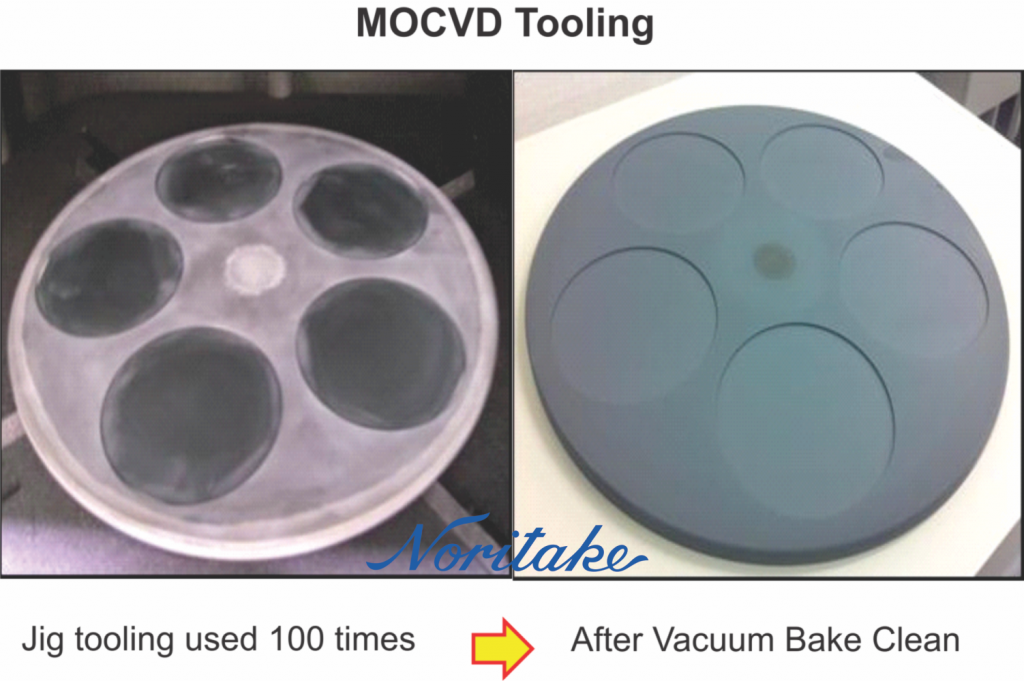

In the critical world of MOCVD processing, the tooling utilized builds up residues of nitride reaction. The vacuum bake cleaner developed by Noritake is a dry-type, enabled cleaning-gas environment. The tooling with deposits of GaN, AlN, etc, is subject to a high temperature in a H2 or CL2 environment resulting in evaporation of the residues and a cleaned tooling. After the cleaning process, the jigs and their coatings (SiC, quartz, etc.) are free of deposits and coatings with their reliability.

Facts

• Dry cleaning without damaging jig surface.

• Non-abrasive dry clean results in less consumables and spare parts

• Non-abrasive dry clean decreases running cost

• No further treatment to the jigs after cleaning, residues are evaporated

• Easy Operation with Auto cleaning system: Run Button Operation

• Large Jig capability

• Large capacity: jig with size of φ800mm, 6 jigs can be processed at once

• Smart design to save floor space

• Clean Room Environment, no wet process, no solvent, no abrassive

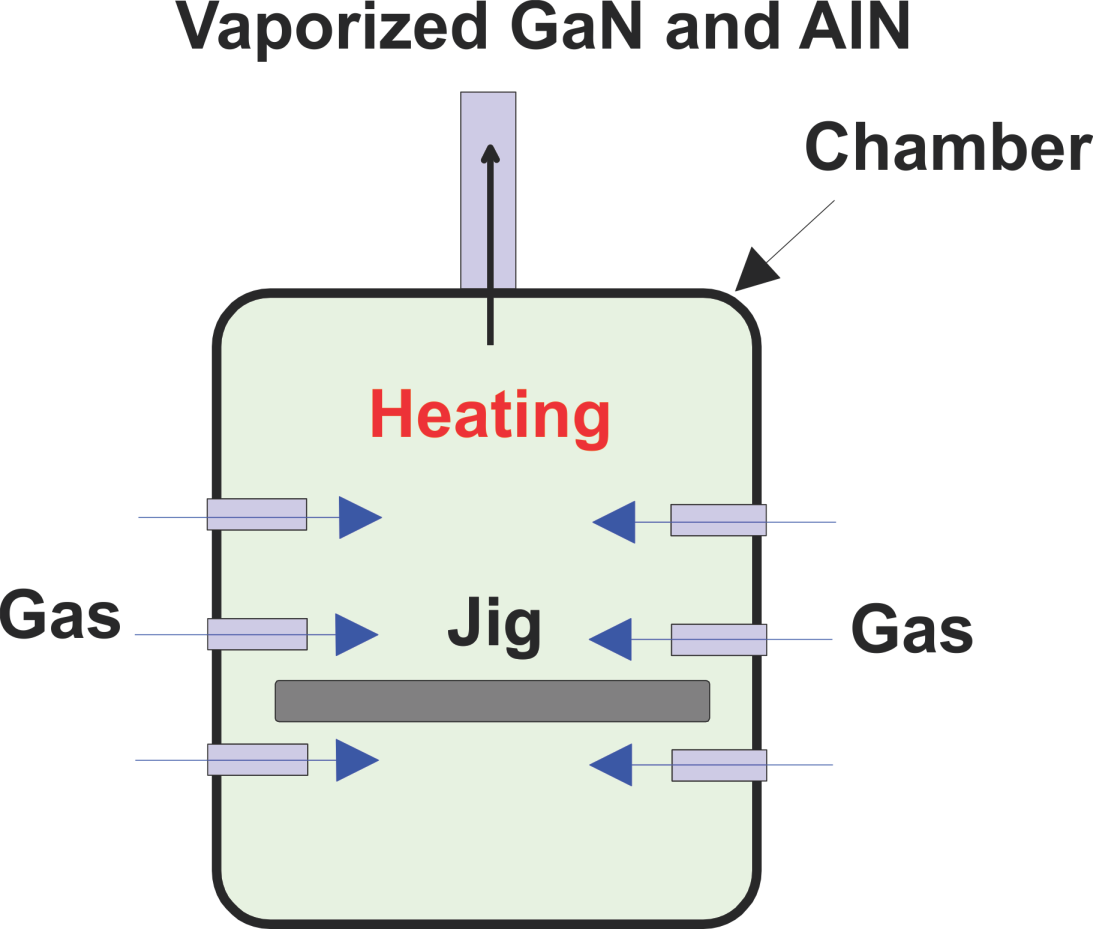

Cleaning Principle

When the jigs are heated up at high temperatures with H2 or CL2 the chemical reaction evaporates the deposits of GaN, AlN, etc., without damaging jigs coatings.

Noritake: 0.1, 0.2 Dry Cleaning (Competitors): 1.5, 1.3 Vacuum Bake (Competitors): 20, 60

*This data is an example, and depends on the film quality and film thickness

- Residual GaN (μg/ml)

- Residual AlN (μg/ml)

Expect LED, Mini and Micro LED, Power Electronics , VCSEL, fabrication yield and quality improvement by NORITAKE

Contact Us

- | Daiichi Jitsugyo (America), Inc.

- | 630 361 6044

- | 630 875 0422

- | Plant & Energy Industry Machinery- PED@djausa.com

- | 939 A.E.C. Drive, Wood Dale, IL 60191

Copyright 2020 All Rights Reserved

1-630-875-0101